<News

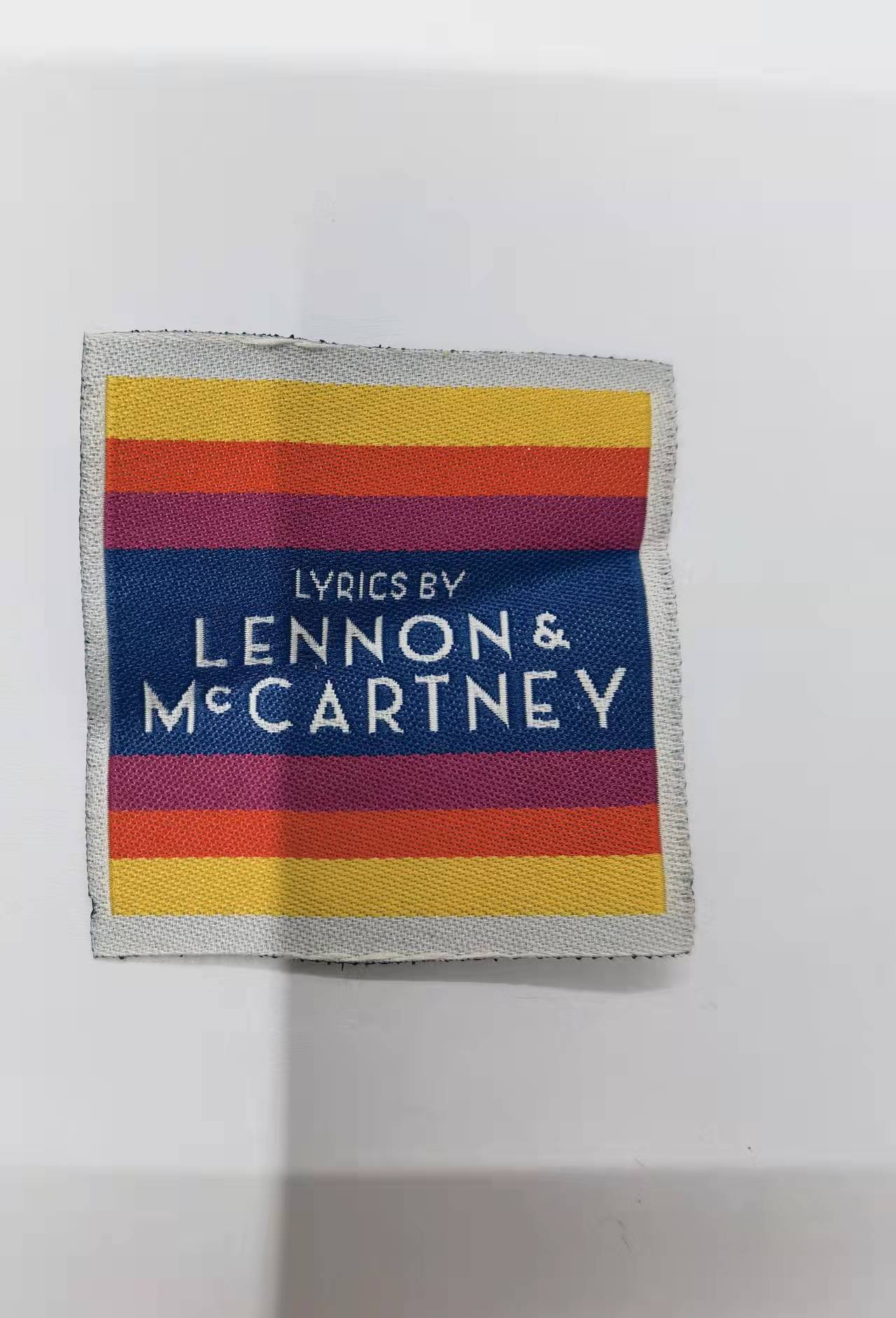

Explore Three Colors of Textile Printing: Vibrant, Sustainable & Stylish Fabric Design

Posted on 2025-10-02

Explore Three Colors of Textile Printing: Vibrant, Sustainable & Stylish Fabric Design

A runway moment where electric blue, moss green, and terracotta red dance across silk—crafted through precision three-color printing.

The lights dimmed, music pulsed, and then came the silence before the storm—a model emerged draped in fabric that seemed to breathe with color. Electric blue surged like lightning through undulating silk, grounded by earthy terracotta red and balanced with soft moss green. This wasn’t just another fashion statement; it was a revelation. Every fold told a story painted not with dozens of hues, but with only three. Welcome to the new era of textile printing—where vibrancy meets sustainability, and minimalism fuels maximal expression.At the heart of this visual symphony lies a deceptively simple technique: **three-color textile printing**. By harnessing the power of primary pigments—strategically layered and precisely aligned—designers are redefining what’s possible on fabric. It's more than an aesthetic choice—it’s a philosophy. Less becomes more when every drop of ink is intentional, every shade purposeful. The result? Patterns that feel alive, dynamic, and rich in depth—all born from a disciplined palette.

Precision alignment in three-color screen printing ensures crisp edges and vivid layering without bleed or blur.

This isn't traditional mass printing. It’s an art form rooted in control and clarity. Behind each piece is a meticulous process known as **trichromatic separation**, where digital designs are broken down into three distinct layers—each corresponding to one core color. These are then transferred onto fine mesh screens, calibrated for exact registration. When printed in sequence, the overlapping tones generate secondary hues and gradients, creating complexity from simplicity. Compared to conventional multi-color methods, the three-color system reduces ink overlap, minimizes smudging, and enhances both saturation and edge definition. The outcome? Crisper lines, bolder contrasts, and a tactile sharpness that elevates any garment from ordinary to iconic.Designers we’ve spoken with describe it as “creative liberation through constraint.” One Brooklyn-based creator shared: *“Limiting myself to three colors forces me to think deeper about composition. I can’t hide behind a rainbow—I have to make every tone count.”* That restraint breeds innovation, pushing artists to explore texture, spacing, and optical mixing in ways previously overlooked.But beauty shouldn’t come at the planet’s expense. That’s why our commitment extends beyond design into sustainability. Each print begins with **plant-based, non-toxic inks** derived from renewable sources—corn, soy, and algae—formulated in labs dedicated to clean chemistry. These pigments travel from bioreactors to bolt rolls with a footprint dramatically lighter than synthetic dyes. In fact, switching to this three-color eco-process slashes water usage by **40%** and cuts carbon emissions by **35%** compared to standard dyeing techniques.We source organic cotton from partner farms in India and Turkey, where regenerative agriculture practices enrich the soil instead of depleting it. There, low-impact dyes meet naturally grown fibers in a harmony few supply chains achieve. No heavy metals. No chlorine bleach. Just pure color, grown and applied with care.

From farm to fabric: organic cotton meets plant-derived dyes in a closed-loop production model.

This synergy has become a catalyst for change—especially among independent labels embracing small-batch production. Streetwear brands use rapid prototyping enabled by digital three-color workflows to test limited runs in days, not months. A Parisian haute couture atelier leverages the method’s precision for intricate overlays on sheer tulle, while a children’s wear label crafts playful, non-toxic prints safe for sensitive skin—all using the same streamlined system. More importantly, the shift toward **on-demand manufacturing** means fewer unsold garments end up in landfills. Styles stay visually cohesive across collections, yet remain flexible enough to adapt to real-time demand.And then there’s emotion—the silent language of color. Psychology tells us that **electric blue** sparks energy and focus, **moss green** fosters calm and connection to nature, and **terracotta red** radiates warmth and belonging. Together, they form a chromatic triad that resonates deeply with human feeling. One user, a certified clothing therapist in Portland, uses garments printed in these tones to help clients express suppressed emotions. *“When words fail,”* she says, *“texture and hue speak. A child wrapped in moss green often relaxes within minutes. A survivor choosing terracotta red finds strength again.”*These aren’t static prints—they’re **kinetic compositions**. Through strategic dot placement and halftone rhythms, designers create illusions of movement, making flat surfaces appear to ripple, pulse, or shimmer under light. It’s fashion as emotional architecture.Looking ahead, the foundation laid by three-color printing paves the way for smarter textiles. Imagine fabrics embedded with microcapsules that shift hue based on temperature—or AI algorithms that optimize color combinations for both ecological efficiency and consumer appeal. By 2030, your wardrobe might include modular pieces with **reprogrammable prints**, refreshed seasonally via app-controlled dye activation. The canvas remains the same; only the story changes.

Concept prototype: responsive textiles using three-color base layers for adaptive, mood-sensitive designs.

Three colors. Infinite possibilities. This is more than a printing method—it’s a movement. One that celebrates creativity within limits, honors the Earth in every stitch, and dresses the world in meaning. Step into the spectrum. Feel the difference. Wear the future.

three colors of textile printing

View Detail >

Contact Supplier